Automotive and Marine Software Services

ASPICE-Compliant Software Development Services

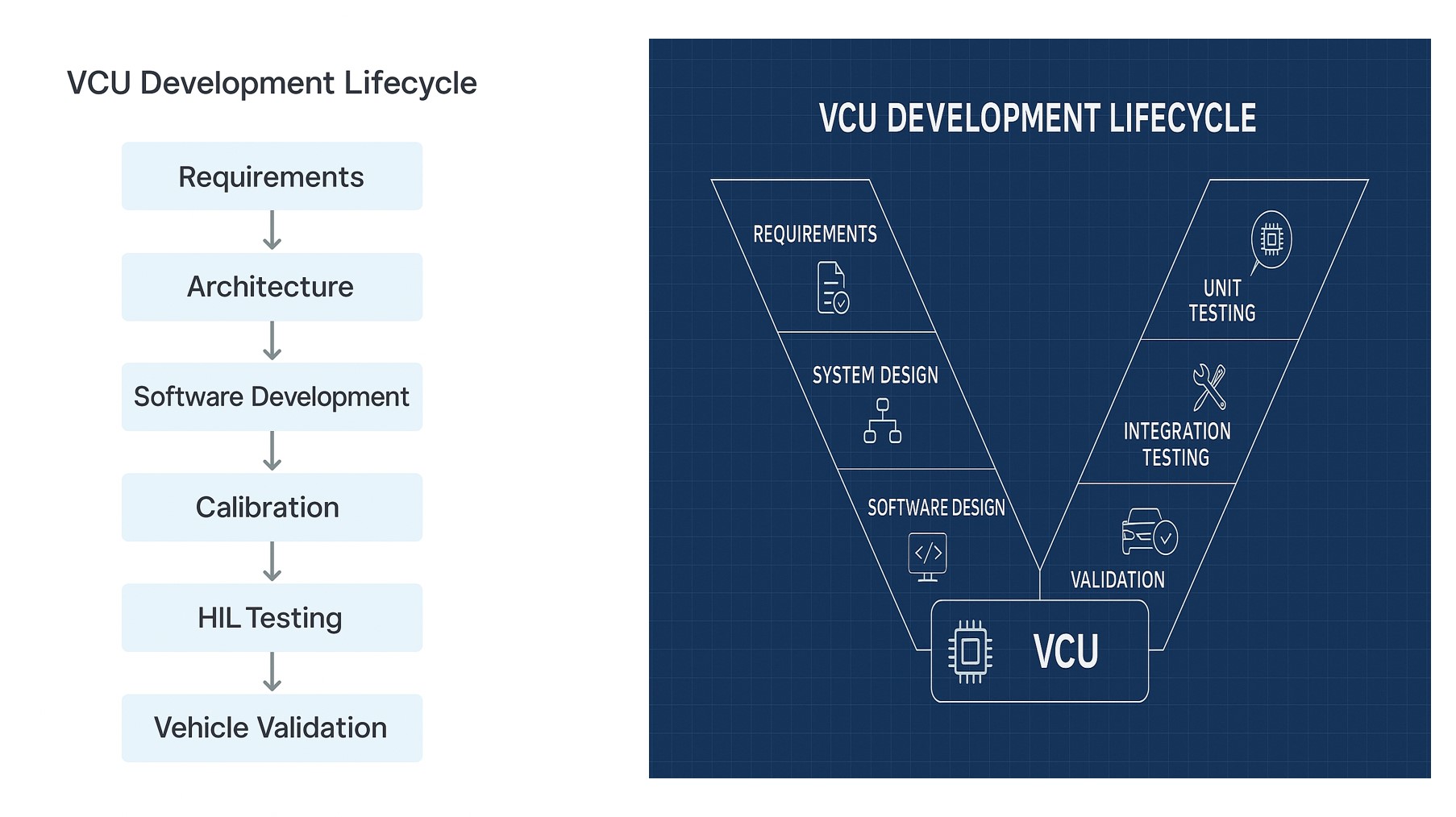

End-to-end automotive software engineering aligned with ASPICE (Automotive SPICE) V-Model

We provide full-cycle ECU/VCU software development following ASPICE best practices from SYS.1 to SWE.6, ensuring high process maturity, traceability, and production-ready quality. Our engineering team supports OEMs and Tier-1 suppliers with scalable, standards-compliant development.

Key Capabilities

Process Excellence

ASPICE Level 2/3-capable workflows

Complete documentation (SRD, SDD, SRS, ICD, Test Specs,

Reports)

CI/CD automation for software builds and tests

Compliance with ISO 26262, MISRA C, and OEM development

guidelines

Domains We Support

Electric Powertrain (VCU, MCU, DCDC, OBC)

BMS & HV Safety

ADAS/Body/Chassis ECUs

Telematics & Connected Vehicle Systems

Hybrid Systems & Energy Management

Automotive and Marine Testing

Manual Test Box (Loadbox)

Precision Loadbox Solutions for Professional, Pin-Level ECU Testing

The Manual Test Box is engineered for development teams who require accurate, controlled, and repeatable manual testing of ECUs. Designed to match exact pinout specifications, it delivers a dependable platform for evaluating functionality, robustness, and fault behavior under real-world electrical conditions.

Key Capabilities

-

Tailored interface designed precisely around your ECU’s pin mapping—supporting analog, digital, PWM, LIN, CAN, and power I/O.

-

Ergonomic switches, variable loads, relays, fault injection points, and toggles provide full control to simulate real-world scenarios and edge cases.

-

Delivered with complete wiring diagrams, load descriptions, test procedures, checklists, and validation reports to support structured testing.

Semi-Automated Loadbox

Next-Level ECU Testing with GUI-Driven Control & Smart Automation

Boost testing efficiency and accuracy with our semi-automated loadbox—designed to eliminate manual effort while ensuring consistent, high-coverage ECU validation. Featuring an intuitive PC-based GUI, engineers can execute complex test actions with a single click.

Key Capabilities

-

Control all pins, loads, and test conditions through a clean, intuitive desktop application.

-

Execute standardized routines instantly—ideal for regression testing, repeated validation cycles, and production checks.

-

Every action, measurement, and result is automatically captured for traceability, reporting, and compliance.

-

Define test limits, thresholds, timing, load levels, and pin behaviors based on your ECU’s requirements.

Automated Test HIL

Advanced Hardware-in-Loop Platform for Full ECU & VCU Automation

Our Automated Test HIL solution delivers end-to-end validation capability by combining real-time simulation, automated execution, and seamless software integration. Designed for high-complexity automotive systems, it enables rapid, repeatable, and fully automated ECU/VCU verification in controlled virtual environments.

Key Capabilities

-

High-fidelity simulation of sensors, actuators, powertrain, chassis, and vehicle dynamics—executed in real time for precise closed-loop behavior.

-

Fully scriptable test sequences with automated execution, monitoring, fault injection, result collection, and reporting.

-

Supports simultaneous testing of multiple ECUs/VCUs with synchronized communication across CAN, CAN-FD, LIN, Ethernet, FlexRay, and analog/digital interfaces.

-

Integrates with CI/CD pipelines (GitLab, Jenkins, Azure DevOps, etc.) for automated nightly runs, regression testing, and continuous validation.

Homologation Readiness Services

Accelerate Certification. Reduce Rework. Launch with Confidence.

Homologation for electric and hybrid vehicles is complex—multiple standards, evolving AIS/CMVR/UN-R rules, and strict behavioural expectations from ECUs, BMS, and powertrain controllers. One failure at the test agency can delay launches by weeks and increase costs significantly.

ECULytics by VG marine closes this gap by preparing your product before it reaches ARAI, ICAT, or GARC etc.

We combine deep expertise in VCU/BMS/MCU software, EV powertrain architectures, and automated HIL testing to ensure your system behaves exactly the way regulations expect.

Our Approach

Understand: We analyse your system, architecture, and

compliance requirements.

Validate: We execute targeted pre-homologation tests using

HIL, simulation, and bench setups.

Optimise: We highlight issues early and support your

engineering team in closing them.

Prepare: We produce agency-ready documentation and

technical submissions.

Support: We accompany you during actual homologation tests

for faster, smoother approvals.

Why OEMs Choose ECULytics by VG marine

Specialised in EV/HEV powertrain, VCU, BMS, and diagnostics

Strong capability in

HIL, test automation, and fault-behaviour validation

Reduces homologation iterations, delays, and cost overruns

Faster time-to-market with

end-to-end documentation and technical support

Flexible engagement—from simple

gap assessments to full lifecycle programs

Our Service Tiers

-

Quick readiness check with actionable findings.

-

Deep behavioural and functional validation to avoid test agency failures.

-

Complete support until product certification.

Requirements Engineering (SYS.1, SYS.2, SWE.1)

Structured capture, refinement, and traceability of system and software requirements using tools like Polarion, DOORS, and PTC.

System & Software Architecture (SYS.3, SWE.2)

Design of modular, reusable, and safety-compliant architectures for powertrain, BMS, chassis, ADAS, diagnostics, and hybrid systems.

Software Unit Design & Implementation (SWE.3, SWE.4)

Model-based development (Simulink) or embedded C/C++ implementation with MISRA, Autosar MCAL integration, and hardware abstraction.

Software Unit & Integration Testing (SWE.5, SWE.6)

HIL/SIL testing, automated scripts, regression testing, interface validation, and coverage analysis.

Configuration & Change Management

Git, SVN, Jenkins CI/CD pipelines, and automated reporting aligned with ASPICE SUP.1/SUP.8.

Verification, Validation & Traceability

Full bidirectional traceability from requirements → design → implementation → tests.